Asset monitoring

Asset monitoring allow for each management of refrigeration equipment, using sensors to take reliable readings that can be used to adjust the fridge temperature as needed.

Keeping a precise fridge temperature can be invaluable for a range of uses. For example, many medical samples require specific temperature settings, and an alarm system can be used to signal the temperatures dropping too low and posing a risk to the biological material inside.

Breathe in. Breathe out.

Setting up a fridge temperature monitoring system can be complex, requiring the installation of remote probes and sensors that can take temperature readings accurately. This requires careful calibration and regular maintenance of every unit to ensure absolute accuracy.

Tyrrell Analytics can be a key part of a new fridge-freezer temperature monitoring system, taking in data from temperature data loggers and transforming it into usable information. Not only can it be the foundation of a fridge temperature monitoring structure, but Simaxx can provide a range of benefits to existing freezer monitoring systems as well.

Step 1

Easy installation & integration

Tyrrell Analytics requires very little work to set up and access, providing high-value software that can link to your data loggers very easily. This can make it a core part of your temperature monitoring methods without disrupting any other operations.

Tyrrell Analytics can integrate seamlessly into existing systems dealing with fridges and freezers. Not only can it be linked to other appliances and tools you use as part of your monitoring methods, but other software platforms that may be relevant to your industry.

Step 2

The Tyrrell Analytics solution is compatible with Building Automation Systems IoT devices, and data collection is automatic. This means that manual measurement records are no longer required, which will mean associated labour savings. Data can easily be visualised in the Historian and Dashboard Apps.

The Tyrrell Analytics platform allows for near-instant recall of any fridge temperature monitoring system data recorded by your data loggers. This allows for maximum details even when looking at compliance issues that are months old or for finding trends in your data.

Step 3

Full Control

Tyrrell Analytics is a facilitator: your freezer temperature monitoring system is still your own, allowing you to follow your own food safety standards, compliance limits, and calibration schedules. This also allows for fully custom alert alarms, different settings for individual refrigerator units, and multiple ways to monitor freezers, depending on your needs.

Step 4

Data Security

Simaxx is a secure software platform that can store refrigerator temperature monitoring data reliably. A range of security features protects your data from theft or tampering while still enabling you to access information on fridges and freezers through a secure device.

Step 6

Compliance

Using Simaxx makes it easier to achieve full HACCP compliance, as well as similar compliance standards with other relevant organisations and industries. This includes things like refrigerator performance standards, medical-storage-compliant temperatures and food safety requirements.

Monitoring temperature using Simaxx allows for a high level of control, especially if the monitoring appliances have been tested thoroughly before installation. Data can be recorded, reformatted and stored however you prefer without losing any readability or accuracy.

There are many applications that would require monitoring the temperature of a fridge or freezer. (e.g. food storage or public health implicated uses.) Simaxx collects critical data which can be visualised and used to alert stakeholders.

Unique fridge temperature monitoring system

The temperature monitoring system you build for your fridges or freezer system will be entirely unique when using Simaxx. Each monitor device and freezer unit set of alarm values will be unique and constructed to suit your needs using a range of high-value software options.

This allows you to fill your data logs with recorded temperatures and freezer alarm information that are specific to your needs rather than working off a template system originally designed for temperatures that are not relevant to your business.

In simple terms, Simaxx allows you to construct a bespoke system that suits your needs and goals. This includes creating unique storage methods and emergency alarms to provide proper monitoring coverage for whatever food, medical equipment or other products you are storing.

Rather than piecing together an entire system from scratch, Simaxx can provide all of the core features you need to monitor temperature-sensitive equipment and freezing units. No matter your industry, this can be an invaluable service and something that the Simaxx software platform is fully equipped to handle.

Automated data collection

By shifting all of IAQ data into one central location, it becomes much easier to analyse everything you have monitored, using that information to build forecasts and find likely causes of particulate matter pollution.

Endless Historic Data

The Simaxx Platform will store continuous data indefinitely, using the highly efficient database structure. This means that the important events are always available to analyse. Graphs can be set up to show different aggregations of the data. This way, Max and Min values can be viewed for a period.

Analysis and alerting

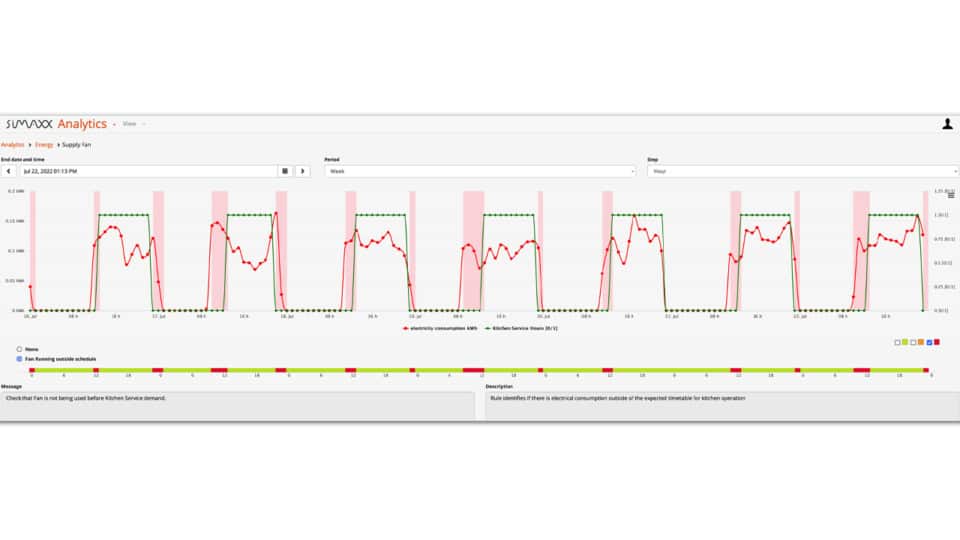

The Simaxx Platform can be configured to trigger events and insights, using the analytic palate. In this way, the responsible stakeholders can receive email notifications when a critical fridge is outside its’ recommended operating temperature.

Solution

Tyrrell Analytics air quality monitoring solution leverage sensor technology and data analytics to ensure that indoor environments are healthy, comfortable, and conducive to productivity. Solution plays a vital role in creating intelligent and responsive building ecosystems that prioritise the well-being of occupants.